WhatsApp)

WhatsApp)

Cement mill Wikipedia, the free encyclopedia The energy efficiency of this process is comparatively high. ... with the cement finished in a single chamber ball mill

Dry Milling,Dry Cement Milling,Dry Milling For Cement Process. Dry milling for cement process Crusher and grinder used for Dry cement milling is the Prehomogenize ...

A NONLINEAR LEARNING CONTROL APPROACH FOR A CEMENT MILLING PROCESS 1 OGUZ H. DAGCI, 2 M. ÖNDER EFE and 3 OKYAY KAYNAK 1 The .

Optimizing the Control System of Cement Milling: Process Modeling and Controller Tuning Based on Loop Shaping Procedures 157 Brazilian Journal of Chemical ...

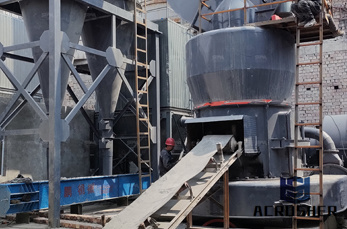

cement plant milling machine process – Grinding . View the interactive animation of the cement production process to learn how cement is made by CEMEX.

Cement Milling Understanding Cement. Overview of cement milling, gypsum addition and dehydration. ... As part of the grinding process, calcium sulfate is added as a ...

Modeling of Sokoto Cement Production Process Using A Finite Automata Scheme: ... clinker process state [3] cement milling state [4] finished cement state

Browse all cement industry Grinding/ Milling supplying companies.

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

THE CEMENT MANUFACTURING PROCESS quarry raw grinding and burning grinding, storage, packing, dispatch ... Présentation PowerPoint Author: sjoguet Last modified by:

whereas the dry cement process consumes MJ/ ton. The high energy consumption of the wet process over the dry can be attributed to the mix preparation .

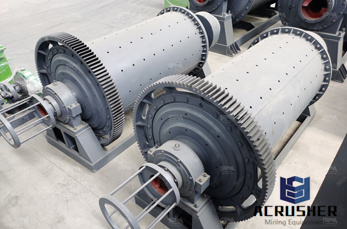

Cement Milling. Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls).

IXMaterialsBCement1 THE MANUFACTURE OF PORTLAND CEMENT Cement is the substance which holds concrete together, which means that it is extremely

Vertical roller mills versus ball mills Soeren Worre Joergensen ... In the grinding process heat will be generated and the cement will be heated up. The

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

Cement Manufacturing Process. The raw materials needed to produce cement ... These naturally occurring minerals are then crushed through a milling process.

The Cement Production Process. Cement kilns are massive cylindrical structures, lined with refractory brick, into which a limebearing material and fuel such as coal ...

· cement milling process,Raw Milling Process In Cement Plant (mill/grinding process of raw mill in cement plant Machine Jump to Fine Grinding

Cement Grinding mill is the main equipment used to grinding cement clinker into cement. Mail to: sales

Ball milling should be considered as a potentially attractive solution for solventfree synthesis. 21 Solvent free Onepot process Tip of iceberg .

Cement raw milling process Raymond Grinding . cement raw milling is binq made excellent mining crushing machinery, we offer you the best of the equipment and ...

In Nigeria, approximately 40 to 50 per cent of cement manufacturing cost is energy related; each tonne of ce ment requires 60 130 kg of fuel oil or its equivalent and

A nonlinear learning control approach for a cement milling . get pdf. read paper. mxico a nonlinear learning control approach for a cement milling process 1 oguz h. dagci

WhatsApp)

WhatsApp)