WhatsApp)

WhatsApp)

Ball mill – Definition | – Dictionary . A ball mill, a type of crusher, is a cylindrical device used to grind (or mix) materials like ores ... ball mill calculation – CGM Grinding Plant Ball mil design calculation? – Yoo!

116 in case of freeform surface 3D milling is changed pointbypoint but in case of 5D milling it can be constant. In the experiment, we determined and compared the tool life of ball nose end mill for upward ramping and downward ...

Summary This review looks at the basic concepts of grinding mills, including their types, principle, construction and usage. It also tells the recent developments in grinding mill manufacturing and provides links to university and ...

The following equation is used to determine the power that wet grinding overflow ball mills should draw. For mills larger than meters (10 feet) diameter inside liners, the top size of the balls used affects the power drawn by the mill.

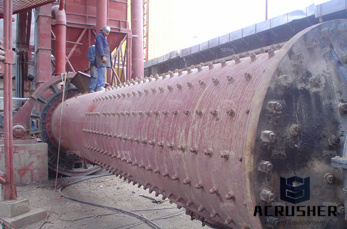

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

Figures for the popular mill types. 3 c is the mill speed measured as a fraction of the critical speed. More reliable models for the prediction of the power drawn by ball, semiautogenous and fully autogenous mills have been ...

IV. BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades. A typical ball mill has an L/D ratio of :1. Ball mills are filled ...

A New Macrophenomenological Concept of Comminution This paper presents a new approach to modelling ball mill grinding: The Operational Model. ... For a determined particle size range, the third theory of Bond. POWDER ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

ball mill types and formula weight feeder formula for raw mill circulating load formula in ball mill ball mill grinding media calculation formula grinding clams formula for calcium carbonate critical speed of ceramic mill formula ...

RTD, Holdup, Ball mill, Ball load, Slurry efficiency of wet milling circuits For a given, as wet ball milling require accurate knowledge of the material, while grinding equations describe the breakage behavior as a function, 75% of critical ...

PDF Ball Milling Ball Milling An efficient and What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. ... PDF TECHNICAL NOTES 8 GRINDING R. P. King The data is taken from Rexnord ...

Grinding Mill Types, Construction, and Usage |, Grinding within a mill is influenced by the size, quantity, the type of motion, Rotation of the rods or balls around their own axes lying parallel to the mill axis, The basic formula for this is ...

Ball mil design calculation? | Yoo Answers Mar 31, 2008· I need to design a l end discharge ball (tube) mill for grinding kaolin as my ... Ball mil design calculation? ... Cement mills are normally driven by ... >> Get Price How Can I ...

types of ball mill – Crusher Price Ball mill manufacturer in India – the ballmilling technique is useful for the preparation of a wide variety of ... types od ball mills – Crusher Price Sugar Mill Instruments – Double R Optics ...

In a ball mill of diameter 2000 mm, 100 mm dia steel balls are being used for grinding. Presently, for the material being ground, the mill is run at 15 rpm. At what speed will the mill have to be run if the 100 mm balls are replaced by 50 ...

Here is your Ball Mill Design/Sizing Procedure. Calculation of top size grinding media (Fred C. Bond) Calculation of top size grinding media AZZARONI''s Formula I attach Fred Bond''s first empirical equation for sizing grinding balls ...

moran: Control the Rotation Speed of Ball Mill Apr 25, 2013 ... The ball mill rotating speed is called critical speed when the outmost ... to calculated, and now only the calculation formula on critical speed in... Archive of SID According ...

The Inner Structure and Main Types of Ball Mill: Ball mill is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. ...

FL – FL Ball Mill Adapts to capacity, plant layout and end product Learn more . The FL ball mill grinds cement clinker, gypsum and similar materials of moderate . ball mill efficiency calculations Capacity ...

Ball mills are horizontal cylindrical shaped equipment that finds application in grinding hard minerals to the form of fine powder. The grinding operation is achieved here through rotation of cylinder with steel grinding balls/ceramic ...

Flutes Spiral cutting edge on the end mill. 2 and 4 flute end mills are the most commonly used. 2Flute Allows maximum space for chip ejection. Used for general milling operations. 3Flute Excellent for slotting. Used for ...

design and analysis of ball mill inlet chute for roller press circuit in (Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker .. As per the chute design formula, the minimum free area of.

What is the formula to calculate mill motor power of ball mill How do you calculate ball mill residence time? mass of mill charge divided by mass flow rate. In empty ball mill power consumption is more or filled why? The Power ...

WhatsApp)

WhatsApp)