WhatsApp)

WhatsApp)

International journal of advanced scientific and technical research Issue 4 volume 1, JanuaryFebruary 2014 Available online on ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. Powerful and quick grinding down to nano range. Read more.

Cement Kiln Process Specialist, expert trouble shooter for process problems with cement kilns.

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

MILWAUKEE M18 FUEL Deep Cut Band Saw With Redlithium XC Battery, Multivoltage charger, blade, and case Get a FREE 2nd Battery until June 30th!

Bolted shell liners, tube mill internals, boltless shell liners for cement mills from AIA Engineering Ltd.

Online daily paper of Galveston, Texas.

How is cement manufactured? Learn cement manufacturing process thoroughly.

Design features of rotary cement kilns ... Riveted construction continued until WWII. The technique of making welded joints in such heavy plate by arc welding ...

Capacity Enhancement and Energy Conservation in Cement Plant Batra*, Chhangani**, Dinesh Satija*** and R. B. Garg**** Holtec Consulting Private Limited, .

Cement Equipment corp. likes. Cement Equipment ( maintenance, inspection ) Cement and clinker Chemistry Cement plant Manufacturing process

Allis Chalmers Svedala ball mill, 13'' diameter x 21'' long, rubberlined mill, with SiemensAllis 2,000 HP, 4000 volt, 200 RPM synchronous motor, Eaton airflex clutch.

Grinding media. Grinding balls are only one type of grinding media. Grinding media are the means used to crush or grind material (cement, mineral, .) in a mill.

Earle''s cement plant: Hope, Derbyshire ... Picture: ©English Heritage NMR Aerofilms Collection. Catalogue number R20367.

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more.

coal hammer mill design[crusher and mill] Hammer Mill Design Mini Project – Free download as PDF File (.pdf), text . The basic design of the industrial hammer ...

The name Ticonderoga, or as the Algonquin and Iroquois Indians called it – Chinandroga, loosely means "the place between two lakes."

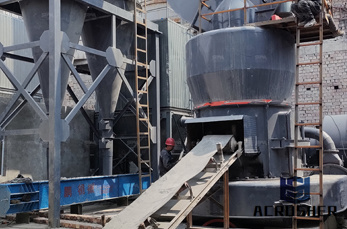

MILL SYSTEMS Main Features Proven Reliability 25 years design and operating experience Over 425 units worldwide Cost Savings Reduced specific power

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Unused FL wet grind overflow ball mill, 27'' ( m) diameter x 46'' ( m) long. Discharge with MW (20,500 kW) gearless wrap around motor drive, 50 Hz ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These are; Raw material extraction ...

A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal for ...

WhatsApp)

WhatsApp)