WhatsApp)

WhatsApp)

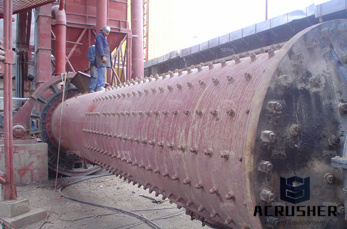

Ball Milling Process Introduction: The ball mill is the key milling machine to break and to smash materials. It also is an effective tool for many materials ground ...

Wet process ball mill . Feeding size:≤25mm Motor Power: Wet process ball mill is widely used in powdermaking production line including cement, silicate ...

A ball mill is a pulverizer that consists of a horizontal rotating cylinder, ... The balls are simply "consumed" by the wear process and must be restocked, ...

Ball mill also can be called ball mill machine or ball grinding mill, is the key equipment for grinding materials after materials are being primarily crushed.

CEMENT GRINDING OPTIMISATION Dr Alex Jankovic, Minerals Process Technology AsiaPacific, Brisbane, Australia email:

Ball Mill Feeding size: ≤20≤25 mm Production capacity: /h Material: alumina ceramics, pebbles, lime, quartz sand, aluminum slag, iron ore, coke, coal ...

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Ball Mill Pendulum Feeder ... Pendulum Feeder is suitable for concentrating coal chemical industry and other departments especially fit for the feeding process of ...

FEATURES Introduction to Ball Mill. Ball mill is a key equipment to recrush primary crushed materials. Ball mills are widely used in cement, silicate products, 52555 ...

Ball Mill 【Feeding size】:≤25 【Discharging sie】: 【Application】:be suitable for grinding(wet or dry) all kinds of ores and other materials.

Ball Mill. Ball mill as most common grinding equipment, play an important role in crushing and mining industry. It can be helpful in the process of metallic powders ...

Ball mill should keep even feeding in operation; the even feeding means stable feeding quantity and same particle size distribution.

Ball mill is one kind of grinding machine, which can be divided into wet ball mill and dry ball mill.

Feeding Conveying; Screening ... ball mill can be either wet or dry designs. Ball mills have been designed in standard sizes of the final ... The ball mill is key ...

Ball mill. Ball mill, a type of grinding mill, is a cylindershaped device used to grind materials like ores, chemicals, ceramic raw materials and paints.

ball mill feed device for feeding of ball mill is a complete system, which has great influence on the ball mill output. The traditional feed form generally has three ...

According to the process condition: 800: 137: Ball mill structure. Hopper; Feeding Tube; Ball Mill; Gear Box; Discharging Chute; Motor; Stone Crushing Production;

ball mill feeding process MTM Crusher. Why is the Bond Ball Mill Grindability Test done the Mill Work Index which expresses the resistance of a ...

Usage: Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

Ball mill machine is key machine that smashes the materials having been crushed, and is widely used in industries like cement, silicate products, new 52555 building ...

dry feeding to ball mill. ball mill feeding process Ball mill,Ball mills,Ball mill machines Machinery. Ball mill is the key equipment for grinding after the crushing ...

Manufacturer of Ball Mills Power Saving Ball Mill, Work Index Ball Mill, Planetary Ball Mill and Laboratory Ball Mill offered by Star Trace Pvt. Ltd., Chennai ...

Raw material mill. Raw material ball mill, also called raw meal ball mill, is important grinding equipment in cement production process. After being crushed, the raw ...

Ball mill is widely used for the dry type or wet type grinding of all kinds of ... Ball mill is mainly composed of feeding part, ... Flotation Separation Process.

WhatsApp)

WhatsApp)