WhatsApp)

WhatsApp)

1. Introduction Because the grinding process to produce pulverized coal results in a broad size distribution, the specific size fraction when pulverized coal particles are injected into a furnace significantly influences the combustion and ...

predict the combustion process of pulverized coal in a 1 MW test furnace. The furnace contains a triplestaged lowNOx swirl burner. A number of simulations were made using several coal types in ...

2005/08/16· The minerals are pulverized to a fine particle size and combined with pulverized coal to provide a mixture of the particles. The mixture is combusted and the ore particles calcine and decrepitate to very fine magnesium oxide Suche ...

CFD ANALYSIS OF THE PULVERIZED COAL COMBUSTION PROCESS IN A BOILER OF A THERMAL POWER PLANT: INFLUENCE OF TILTED INLET FLOW OF FUEL AND AIR ON THE NO ...

Coal Dust Explosion Hazards Mine Safety and Health Administration pulverizedfuel systems, grinding mills, and other process or conveyance ... coal is reduced ... Brevetto US Reduction of coalfired combustion ... The ...

The process of pulverized coal size reduction MODELING OF PULVERIZED COAL COMBUSTION FOR . Modeling of pulverized coal combustion ... effective measure for reduction of NO x emission from pulverized coal ... complex ...

CFD Approach for Unburned Carbon Reduction in Pulverized Coal Boilers Jun Li,*,† Radosław Jankowski,‡ Michał Kotecki,‡ Weihong Yang,† Dariusz Szewczyk,‡ Artur Brzdekiewicz, and Wlodzimierz Blasiak† †Division of Energy ...

NOxReduction in a Pressurized Pulverized Coal Flame by Flue Gas Recirculation C. Fielenbach, Th. Holfeld, C. von Petery, U. Renz WÜK, Aachen University, Germany Wünning WS Wärmeprozesstechnik , Renningen ...

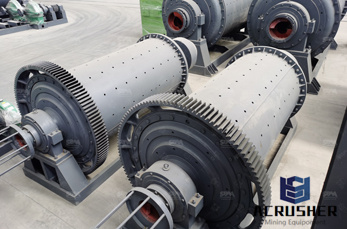

Types of coal pulverizers Coal pulverizers may be classified by speed, as follows: Low Speed Medium Speed High Speed Low Speed Ball and tube mills A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to ...

2015/03/08· Carbothermal Reduction of Boronbearing Iron Concentrate and Melting Separation of the Reduced Pellet Guang Wang ...

Power plant Coal Crusher – uniform size reduction – less fines Coal crusher, single stage, two roll installed in power plant to replace hammermill crusher that was generating too many fines for coal fired boiler. ... The crusher is processing ...

Pulverized Coal Injection (PCI) is a process that involves blowing large volumes of fine coal granules into the BF. This provides a supplemental carbon source to speed up the production of metallic iron, reducing the need for coke ...

2017/08/15· [Show abstract] [Hide abstract] ABSTRACT: The influence of coalparticle size on nitrogen oxide (NOx) emission and burnout characteristics was experimentally investigated in a pulverized coalfired furnace. This study ...

Size reduction or comminution of bulk solids is a very common and important unit operation found across the process industries. Liberation of a key species (ores), improved chemical activity or bioavailability (catalysts ...

Latest LowNOx Combustion Technology for Pulverizedcoalfired Boilers 188 improvement has been achieved by developing better burner combustion methods for use in furnaces. This paper summarizes the latest lowNOx combustion

Pulverized Coal Injection | Industrial Efficiency ... Pulverized Coal Injection (PCI) is a process that involves blowing large volumes of fine coal granules into ... Development of Waste Plastics Injection Process in Blast ... with decrease ...

Graphical abstract This paper describes a new process of solid state reduction of Panzhihua titanomagnetite concentrates with pulverized coal. In this process, the titanomagnetite concentrates was preoxidized firstly and then ...

NO, REDUCTION IN PULVERIZED COAL COMBUSTORS USING WASTE COAL AS COALWATER SLURRY Sarma V. Pisupati and Vlad Zornescu Energy and GeoEnvironmental Engineering Department, and The Energy Institute ...

recommendations for, a novel radiativelyconductively stabilized combustion (RCSC) process for pulverized coal, which, based on our prior studies with both fluid fuels and pulverized coal, holds a high promise to reduce NO ...

1970/11/17· A process for mitigation of fouling deposits within a combustion zone, capturing of toxic metal emissions, and reduction of visible sulfur emissions attributable to sulfuric acid mist during coal combustion. SO3 formed ...

USE OF COAL DRYING TO REDUCE WATER CONSUMED IN PULVERIZED COAL POWER PLANTS FINAL REPORT December 2, 2002 to March 31, 2006 by Edward K. Levy Nenad Sarunac Harun Bilirgen Hugo Caram

pulverized coal size reducing process Stone crushing equipment is designed to achieve maximum productivity and high reduction ratio. From large primary jaw ... pulverized coal size reducing process Ore Crusher, Ore . Pulverized coal ...

Process for reducing sulfur contaminant emissions from burning coal or lignite that contains sulfur US A Abstract A process for preparing a coal or lignite fuel that contains sulfur for combustion wherein reduced amounts ...

Vol. 44 No. 2 2011 1 Advanced Development of Pulverized Coal Firing Technologies TAMURA Masato : General Manager, Combustion Engineering Department, Power Plant Division, Energy Systems Operations WATANABE Shinji : Combustion Engineering Department, Power Plant Division, Energy Systems Operations

WhatsApp)

WhatsApp)