WhatsApp)

WhatsApp)

how to reduce energy in the cement mill Reduce Energy Consumption Cement Production Reduce Energy Consumption Cement ProductionFor example a steel mill .

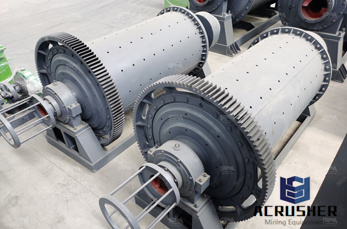

Traditionally, ball mills are used in cement industry for raw material, fuel and ... and holding a potential to reduce energy consumption by 500 GWh (NDRC, )...

Sep 01, 2017· EMAX High Energy Ball Mill Retsch. The Emax is an entirely new type of ball mill for high energy milling. ... Reduce Energy Consumption: Cement .

how to reduce energy in the cement mill | Solution for . Cement mill including cement ball mills and cement vertical mills . Cement mill includes cement ball ...

ABB drives in cement | 9 Applications Mills In cement production, mills are process critical. Reliable ... reduce wear and save energy. For maintenance inspection,

When it comes to achieving the best energy ... For electrical energy, options to reduce ... Correct timing on the maintenance of a first chamber cement mill ...

CEMBUREAU Electrical energy efficiencyCement manufacturing How To Reduce Energy In The Cement Mill mainly uses electricity to .

AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING ... Available and Emerging Technologies for Reducing Greenhouse Gas ... of the cement can be done in ball mills, ...

A cement mill (or finish mill in ... The recent history of the technology has been mainly concerned with reducing the energy consumption of the grinding process ...

Several grinding methods are available in cement industry depending upon the material to be ground. In cement production process, about 26% of the total electrical ...

Energy Saving Cement ... towards dry process to reduce energy consumption in the cement ... of a trass mill process in a cement plant. Energy ...

Reduce Energy Consumption: Cement Production ... A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, ...

as well as different strategies to reduce energy use and greenhouse gas emissions For many concrete products,, ... and classifiers on cement mills, ...

Ways to achieve energy saving in Cement. People grind materials while reducing size, power consumption can beFor example, to new vertical mill, grinding, and other ...

Reduce Energy Consumption: Cement Production How conducting manufacturing energy assessment can help identify a wide range of changes to help reduce .

how to reduce energy in the cement mill | Solution for, Cement mill including cement ball mills and cement vertical mills, Cement mill includes cement ball mills ...

201 The cement industry | Global CCS Institute. Most of the CO2 emissions and energy use of the cement industry are related to, 2009) and the exhaust fans (kiln/raw ...

Energy Efficiency and Saving in the ... Yet another way to reduce energy and process emissions in cement production ... (and hence energy costs) at tube mills is ...

Find energy market research reports and pharmaceuticals industry analysis including industry overviews, market segmentation data, market share and growth.

how to reduce in cement mill myzeecompus how to reduce in cement mill it is the cement companies?¡¥ great demand about how exactly to cut back the energy ...

Design and Optimization of Ball Mill for Clinker Grinding in Cement Plant. ... energy saving and emission reduction to reduce energy consumption of ball mill is ...

Energy optimization in cement manufacturing ... mills and filters to an ex ... reduce energy consumption and main

MULTIPLE WAYS OF ENERGY CONSERVATION COST REDUCTION IN CEMENT ... kilns and cement mills, ... energy efficiency and reducing the energy cost for the cement industry ...

Determining cement ball mill dosage by. Determining cement ball mill dosage by artificial intelligence tools aimed at reducing energy consumption and environmental ...

WhatsApp)

WhatsApp)