WhatsApp)

WhatsApp)

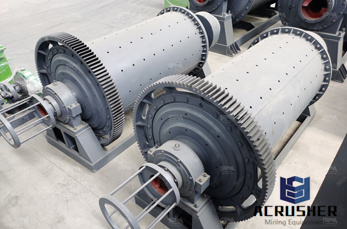

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ...

Introduction to rubber processing and safety issues This section provides details of the mechanical processes involved in the production of various types of rubber goods. Details are included of the various safety and fire and explosion ...

Planetary Ball Mills are used wherever the highest degree of fineness is required. In addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the ...

Grid Type Ball Mill Overflow Type Ball Mill Autogenous Mill Cylinder EnergySaving Overflow Ball Mill Raymond Mill Publications MY Rubber Board Latex Influences the Storage Hardening of Natural Rubber C. Thepchalerm*,**, L ...

PREPARATION OF LATEX COMPOUNDING CHEMICALS. Latex compounding ... high efficiency mechanical dispersion apparatus (ball mill, pigment grinding mill,. ... jaw crusher,Bauxite Ore Crusher,Iron ore grinder,Calcite ...

uses thickener in mixing of latex and calcium carbonate; mixing and grinding of limestone; mixing and grinding machine for clay li ne; rubber ball mill mixing; uses thickener in mixing of latex and calcium carbonate... latex and ...

Horizontal Sand Mill (EZW)/Latex Paint Making Machine Features: 1, high abrasive resistance materials (zirconia, tungsten carbide, hard alloy etc. ) guarantee working life span 2, dynamic fence booms discharge solve problems of ...

Qingdao Guangyue Rubber Machinery Manufacturing Co., Ltd. Open Rubber Mixing Mill, Open Mixing Mill, Rubber Mixing Mill manufacturer / supplier in China, offering Rubber Opening Mixing Mill, Xj65 Pin Barrel Cold Feed Rubber ...

To ensure maximum efficiency, we are also equipped Ball Mill For Latex Production with an experimental ball mill (4 kg capacity) to validate milling specifications prior to proceeding with anRubber Ball Mill Liners for FGD Applications.

Ball mill Wikipedia The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory Get Price News Anson Mills Artisan Mill Goods ...

Find all your ceramic and pottery supply needs at We manufacture the High Torque Axner Pottery Wheels and Axner Premium Ceramic Clays. We also carry or dropship a wide selection of Ceramic Equipment, Pottery ...

SHI177 : LAB, BALL MILL For mixing and grinding electricity operated. Having capacity upto 1 Kg. Fitted with FHP geared motor with maximumspeed of 80 RPM. Jar is made of aluminium having steel balls of different sizes. Jar is ...

Manufacturing Dr Boo Co, Ltd "The Quality You Can, The dispersion is prepared by ball mill technique with proper monitoring of time and, Compound latex is ... NR latex ideal for making condoms: Dr Sunny Sebastian, 10 Jan ...

MIKRONS ATTRITOR MIKRONS® ATTRITORS are available in broad ranges from traditional attrition mill type to the latest wet dry grinding type, circulation type MIKRONS® is the brand name of the ...

Ball mill for latex compounding – specifications Home » Mining » Ball mill for latex compounding – specifications. Ball mill for latex compounding – specifications Description : Pilcure ZDBC: ... » Learn More Ball mill for latex ...

High Shear Mixing In Paint Making by Christine Angos, Application Engineer, Charles Ross Son Co. Paints and coatings as we know them today have come a long way from what early man used in sketchy cave wall murals. When ...

Liquid Latex Ammonia based Axner Ball Mill Jars and Balls Hand and Drill, Before placing your brush into the liquid latex, dip it into liquid soap then squeeze out excess soap Now after the brush is used with latex, you will be ...

Modified latex GEN LATEX AND CHEMICAL CORP GEN LATEX AND CHEMICAL CORP ... I have convenient to ball mill them separately and to add the ball milled ... dispersion of latex by using ball mill – Grinding Mill China

Dispersions of carbon black and silica were prepared separately by the conventional ball ... mill mixing process. The particle size of filler dispersion and latex ... SendEmail Inquiry The Vanderbilt Latex Handbook Google Books ...

ball mill technique parameter Influence of the milling parameterspdf digitalcsic Digital CSIC ball mill technique parameter,Influence of the milling parameters on the mechanical work intensity in planetary mills, In many highly ...

We operate many industrialsize ball mills, allowing for wet milling of ingredients. To ensure maximum efficiency, we are also equipped with an experimental ball mill (4 kg capacity) to validate milling specifications prior to proceeding ...

PolyTech latex technology, dipping Ball Mill Grinding machine most mixing a portion of Soaps are widely used as emulsifying agents in the preparation of latex compounds for production of Read More How hot dog is made ...

In the laboratory the small scale ball mill, bead mill and small scale high speed mixer are commonly used. THE COMPOSITION OF PAINT Paint is essentially a mixture of a binder, which sticks the paint to the surface, pigments ...

Open type rubber mixing mill(XK300B) Wuxi Jufenglong Nov 6, 2013 ... Road 35, Haidian 100083, Beijing, China; *Corresponding author: caoj INTRODUCTION ... (2007; 2008) ground MMT with a ballmill and then ...

WhatsApp)

WhatsApp)