WhatsApp)

WhatsApp)

slide 1: Process introduction The coal mill can be divided into low speed coal mill medium speed coal mill and high speed coal mill.

Nonlinear coal mill modeling and its application to model predictive control. ... In this paper a three state coal mill model based on heat and mass balances as ...

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing,...

Coal Mill for sale From China Zenith. Zenith Coal Mill for silicate, cement, ceramic, chemical fertilizer.

Coal mill is an important auxiliary equipment for coalpowder furnace, it has three methods to crush the coal lump and grind them into powder,it is crushing ...

consumption of coal in coal mill | Solution for ore mining. coal crusher and coal mill is the best coal processing machine in the power . Coal Crusher|Coal ...

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace.

Coal Mills are the Heart of a Coal Fired Plant Maximum capacity, reliability and performance of your operation rely on the critical roles that your coal mills perform:

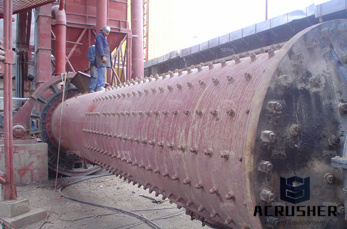

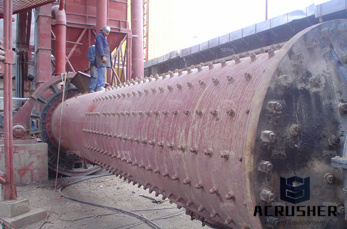

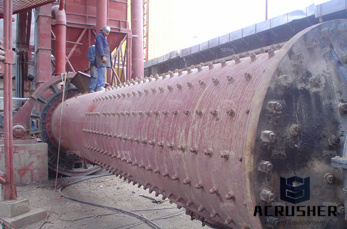

Coal mill is the equipment that is used to crush the coal and grind it into the coal powder.

Mill Rejects (Pyrites) Oil Ash; Silo ... With nearly 1000+ of mill reject ... tramp metal and other rejects from coal pulverizers does not have to be accomplished ...

Daw Mill was a coal mine located near the village of Arley, near Nuneaton, in the English county of Warwickshire. The mine was Britain''s biggest coal producer. On 7 ...

Coal mill is the equipment used for grinding and drying coal with different hardness and it is mainly composed of feeding device, principal axis, rotating part ...

The airswept coal mill can grind coal from 25 mm into Electric engine and Diesel engine are from 3t/h to 40t/h flexible.

Small size, big energy savings 2 Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations.

LOESCHE developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h. More technical information. Raw Mills. Coal Mills.

Coal Mill and Coal Feeders Download as PDF File (.pdf), Text File (.txt) or view presentation slides online.

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal ...

Find all the manufacturers of coal grinding mills and contact them directly on DirectIndustry.

Indications for maintenance: Reduced mill capacity Increase in spillage Incorrect coal fineness Noise level . Wearable mill parts: Grinding rolls Bull ring segments ...

AirSwept coal mill is ideal equipment for coal preparation and widely used in industries including cement, power generation, metallurgy industry, chemical industry, etc.

Performance Driven Maintenance of Coal Pulverizers ... All coal pipes from a single pulverizer will usually have varied ... This was a ball tube mill and the issues ...

Coal Grinding Mill, Wholesale Various High Quality Coal Grinding Mill Products from Global Coal Grinding Mill Suppliers and Coal Grinding Mill Factory,Importer ...

Exploring ball size distribution in coal ... to maintain a steady balanced ball charge in the mill. ... that the coal feed to this plant is known to be ...

Coal Mills at Klinger Machinery. Klinger Machinery Company, Inc. PO Box 306, Elizabethville Pa. . Tel ... Complete Coal Mill. Also Spare Parts. 1:

WhatsApp)

WhatsApp)