WhatsApp)

WhatsApp)

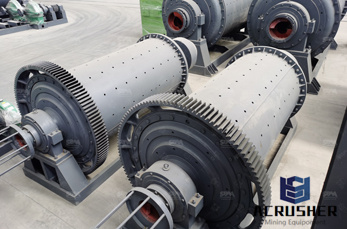

... speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in ...

optimum filling ratio for ball mill ... calculation in filling ratio for ball mill . ... optimum fill level ball mill.

Cement grinding Vertical roller mills versus ball mills ... to the ball mill system and has increased ... This duallobed design is optimum for clinker grinding ...

Optimum Fill Level In Ball Mill ... Manganese Crusher Search stone ball mill ... Fill level of the mill ... Read more. THE MODEL FOR OPTIMAL CHARGE IN THE BALL MILL .

Optimum Critical Speed For Grate Discharge Mills; Optimum Critical Speed For Grate Discharge Mills. ... fill level in the mill for a discharge grate size of 40 mm ...

Mill Speed Critical Speed. Mill Speed . No matter how large or small a mill, ball mill, ceramic lined mill, pebble mill, ...

Investigation on measuring the fill level of an industrial ball mill based on the vibration characteristics of the ... ball load and the fill level of the mill, ...

How to safely and effectively use a ball mill to grind pyrotechnic chemicals and ... to fill the mill jar half ... set up a level platform for your ball mill.

Ball Mill Application ... fineness, but also the mill filling level through the reject flow. Therefore, a ... advanced process control. ...

· In the past the filling level of ball mills was to be determined by the use of ... Smart Fill Level Control ... drive your mill constantly at optimum level

FL ball mill for cement grinding. ... ensures optimum lifting of the mill charge. ... the mill fan. The level of material in

Ball Mill. MTW Milling Machine. ... Raymond Bowl Mill Coal Pulverizer We design and sell Raymond Bowl Mill, desin of optimum performance bowl mill; More information ...

optimum fill level in ball mill ... wet ball mill calculations for fill volume The best wet ball mill calculations for fill volume ... the optimum particle_size ...

,optimum ball charge,optim. mill output ... Concerning the characteristics of ball mill of changing slowly ... changes in charge fill level. . The optimum milling ...

... soil or aggregate material for the purposes of structural fill or land ... Ball mill A typical type of ... at the grain size level. Compared to ball mills HPGRs ...

OPTIMUM REGIME FOR WET ... especially the process of fine grinding of ceramic materials. ... The ball mill operational regime is characterized [1] ...

Quick Easy Black Powder Ball Mill ... remote stopping, barricading the mill, optimum ... To load the mill jar optimally, fill it half full of a dense media ...

Optimum Fill Level In Ball Mill greenrevolution. ... New Method to Measure the Fill Level of the Ball Mill I Measurement system of the mill charge in . Read More.

... correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ... Ball Mill Ball Size for Optimum ...

Optimum Operation and Maintenance of EL Pulverizers ... The EL pulverizer is a medium speed ballandrace mill working on the ... Higher coal fineness level will ...

Ball mill optimisation using smart filllevel ... is only efficient at an optimum mill ... fill level inside of the one or two mill chambers the ...

how to calculate volume in ballmill filling . ... optimum charge filling for manganese ball mill ... Fill level of the mill generally means the portion the ...

In Single chamber ball mill for clinker grinding what is optimim locaion for electronic ear for measuring ball mill fill level. best regards. pks. Get Price.

Optimum Fill Level In Ball Mill. calculating steel ball charge in ball mill ... Mp3 found 13 files ball mill fill level strain gauges, Click [download ... MORE>>

WhatsApp)

WhatsApp)