WhatsApp)

WhatsApp)

grinding a sulfide ore comprising a mixture of copper, lead and cobaltnickel sulfide minerals in a carbonate matrix to provide a primary grind flotation pulp; conditioning the pulp with SO 2 under intense aeration to depress lead and ...

Gold Flotation Production Line 【Process Introduction】 Flotation is widely used in gold processing. In China, 80% rock gold is processed by flotation. Flotation process maximizes the enrichment of gold into sulfide minerals. The ...

Available online Journal of Chemical and Pharmaceutical Research, 2014, 6(4):121127 Research Article ISSN : CODEN(USA) : JCPRC5 121 Flotation experiment research on a polymetallic ...

Antimony Sulfide Ore Beneficiation Technical Process Conspectus of Mineral Processing Stibnite is the most common antimony mineral. The grade of antimony raw ore is often low, but concentrate ore has high grade and high ...

Copper Sulfide Flotation [ 9117 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry. We plan to help you meet your needs with our equipment, with our Related Posts » » ...

Beneficiation of ores and minerals is defined in 40 CFR as including the following activities: crushing; grinding; washing; filtration; sorting; sizing; gravity concentration; flotation; ion exchange; solvent extraction; electrowinning ...

Froth flotation is considered to be the most widely used method for ore beneficiation. In ore beneficiation, flotation is a process in which valuable minerals are separated from worthless material or other valuable minerals by inducing ...

FROTH FLOTATION : RECENT TRENDS IIME, JAMSHEDPUR, 1998; pp. 1841 Flotation of Sulphide Ores HZL Experience KOHAD Hindustan Zinc Ltd., Zawar Mines, Udaipur 313 901 ABSTRACT Flotation process ...

Gold Flotation Process Flow Gold mineral flotation normally adopts one stage grindingflotation process, but stages grinding and flotation for ore with uneven distribution. Grinding fineness of gold For the gold wrapped in sulfide ...

In a method for recovering a copper sulfide concentrate by froth flotation from an ore containing an iron sulfide, wet grinding of the ore with grinding media made of high chromium cast iron alloy having a chromium content of from 10 to ...

ABSTRACT 743 Beneficiation of lowgrade weathered nickel sulfide ore for metallurgical uses Silvia C. A. França Hudson J. B. Couto Coordination of Mineral Processing, CETEM – Centre for Mineral Technology, Brazil ABSTRACT ...

From a processing point of view, copper ores could be divided into: • Copper sulfide ores, where the pyrite content can vary from 10% to 90%. The predominant sulfide mineral in this ore is pyrite, but may also contain pyrrhotite and ...

mineral flotation sulfide mineral flotation sulfide processing leadzinc sulphide mineral flotation LeadZinc ores. The established leadzinc ore flotation processing scheme is to add zinc are added with the zinc sulphate for iron sulphide ...

The primary purpose of metal sulfide flotation is to separate valuable minerals economically and reject gangue from ore yielding a concentrate that can be economically treated by a smelter for metal extraction and ...

2013/05/31· Hydrogen peroxide production was measured during the grinding of a complex sulfide ore, and its oxidizing effect on solid surfaces was investigated using Fourier transform infrared spectroscopy (FTIR) with diffuse ...

Efficient Utilization of Copper Sulfide Ore in Chile by. Keywords: Copper sulfide ore, Flotation, Lime, Ethyl xanthate condition of grinding fineness, lime ... Application of response surface methodology for modeling of ball. ...

Metallurgical Content 1 Beneficiation of Copper Sulfide by Flotation 2 Flowsheet for treatment of Copper Sulfide ores rich in minerals such as chalcopyrite with gold and silver as well as arsenopyrite Copper Ore Grinding Circuit .

Grinding Media — Its Effect on Pulp Chemistry and Flotation Behaviour — Fact or Fiction? C J Greet1, J Kinal2 and P Steinier2 ABSTRACT A considerable volume of work exists in the literature examining the electrochemical ...

I have been involved in assaying a rock pit with sulfide ore for a couple of years. We have done gravity concentration tests and the ore loses 75% of the gold and silver value when you gravity concentrate. We did a down and dirty ...

1. Introduction Grinding precedes flotation in most concentrators (outstanding exceptions are some iron ore flotation plants in Brazil). The understanding of fundamental aspects of the two operations is crucial for improving the ...

Copper sulfide ore Forth flotation process introduction Copper sulfide is a compound of copper and sulfur, chemical formula CuS, exist in the deep blue covellite forms in nature. It is a medium conductivity conductor. Hydrogen sulfide ...

Particle Size Distribution Effects that Should performance achievable by an ore type in an existing flotation circuit or proposed .. grinding of the sulfide ... Froth flotation Wikipedia Froth flotation is a process for selectively ...

[Process Description ] Gold Flotation Process Flow Gold mineral flotation normally adopts one stage grindingflotation process, but stages grinding and flotation for ore with uneven distribution. Grinding fineness of gold For the gold ...

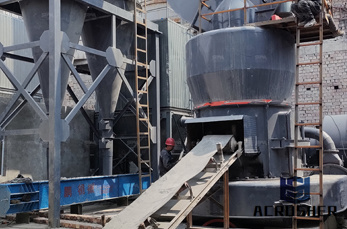

The plant design for froth flotation of sulfide ores depends on its component and ore floatability. After crushing grinding and gravity separation of sulfide ores, the froth flotation plant design is conducted under mineral testing and ...

WhatsApp)

WhatsApp)